What is Perlite?

WHAT IS PERLITE?

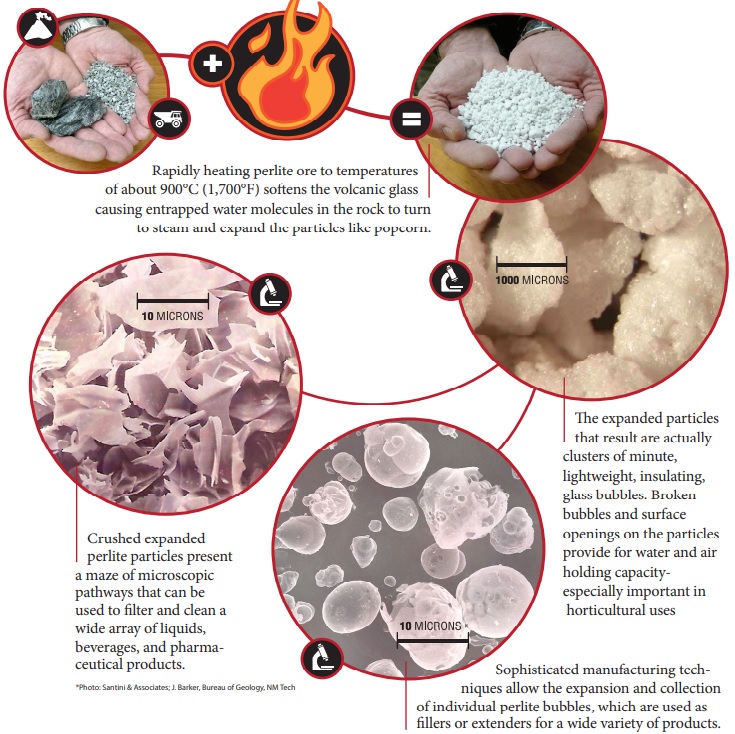

Perlite is not a trade name but a generic term for naturally occurring siliceous volcanic rock. When heated to a suitable point it expands four to twenty times its original volume. Crude perlite rock contains 2 to 6 percent water which is the contributing factor of the expansion. At approximately 1600 ̊F the raw ore pops in a manner similar to popcorn. Perlite does not create by-products during processing; only the physical form is altered.

Expanded perlite can be manufactured to weigh from 2 lb/ft³ to 15 lb/ft³ making it adaptable for numerous uses including filtration, horticultural applications, insulation, and multitude of filler applications. The particle size of expanded perlite is an important factor how it works in a given application. Other factors such as physical structure and density can also be critical in certain applications.

Perlite is a natural, versatile mineral that is abundant, lightweight, insulating, and non-flammable. Some typical applications are garden & soil amendments, insulating concrete, masonry loose fill, and filter aid. Products are made from all particle sizes and densities making perlite an efficient, “no waste” industrial mineral.